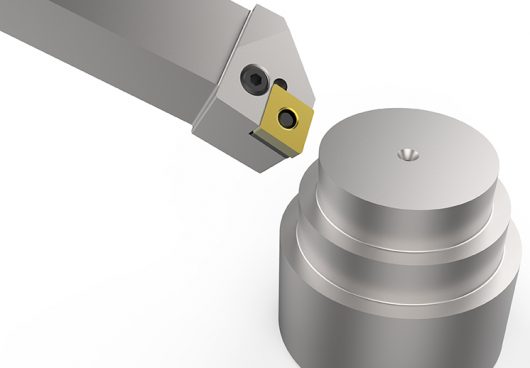

Turning is a production process to remove material from a cylindrical piece in order to transform it into the desired shapes and dimensions.

The material is removed by the rotation of the workpiece and by the mostly straight motion of the tool.

The applications that can be obtained through this operation are many: it can range from heavy roughing up to the extreme finishing.

Our solutions

The products related to turning, selected and proposed by Angelo Ghezzi & C. Spa, find greater range in the Talicarb program “Tools & indexable Inserts”, while in the Talicarb brazed program there are some turning tools for more traditional uses.

Our ISO inserts, available in different grades of carbide and with chip breaker geometries specific to each application, are suitable for all machining of both roughing and finishing, on all types of material.

In addition to the solid carbide proposal, in our new catalogue Talicarb .21, some technologically advanced cutting materials such as CBN, PCD and CD have been introduced. Specifically, the program includes both positive and negative inserts, integral or with brazed tips. These advanced solutions can be used for turning the following materials: steel and cast iron of high hardness, aluminum, light alloys and some abrasive materials.

The range of steel toolholders includes systems for external and internal turning. In case of high tool protrusion, our program provides solutions in solid carbide or HSS able to reduce vibrations during machining. These tools, as well as other steel bars, are equipped with holes for the internal coolant.