Milling is a chip removal machining through which it is possible to obtain a wide range of surfaces (flat face, shoulders, grooves).

The working cycle normally involves a first phase of roughing, in which the removal is carried out as quickly and economically as possible.

The finishing, through the removal of a smaller volume of metal compared to the roughing, allows to respect the tolerances of the required dimensions and the requested roughness values of the surfaces.

In recent years, in order to meet the needs of the market, innovative milling strategies have made it possible to accelerate the machining processes with chip removal. With the introduction of new CAM software versions, multitasking machines and new generation tools, it is possible to achieve a significant increase in chip volume compared to the conventional milling.

Our solutions

In the field of milling, the company Angelo Ghezzi & C. Spa, can offer wide-spectrum proposals.

The selection of TALICARB products represents our most complete and advanced program in terms of milling.

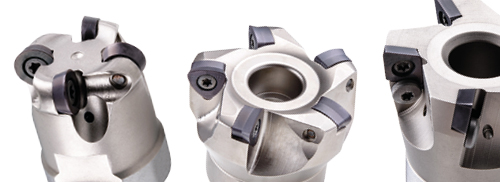

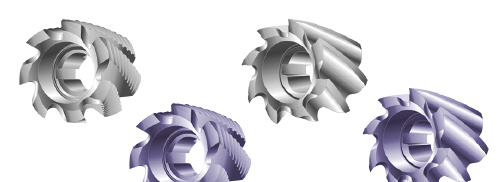

In the range with indexable inserts it is possible to identify various toolholders to realize face milling, plunging, helical interpolation and trochoidal milling. Our inserts, with different grades and coatings, are able to work a wide range of materials.

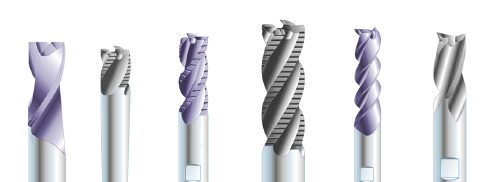

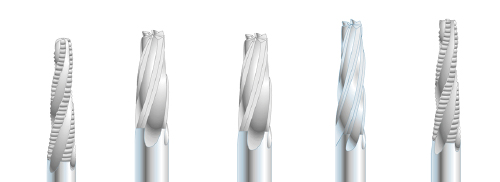

The program of solid carbide end mills is also complete, passing from the traditional end mills to the more advanced ones for molders. For customers who still use conventional machines, who need large diameters or special cutting lengths, the Talicarb brazed tools program still represents an excellent compromise for some specific milling applications.

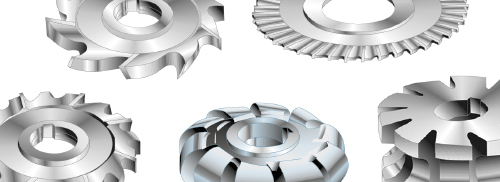

The ILLI.Co program identifies HSS-Co and HSS-Co PM milling cutters with 2 or more flutes produced according to the current standard DIN and available in various lengths and coatings. In the range are proposed different profiles for finishing or roughing, depending on the machining that must be performed.

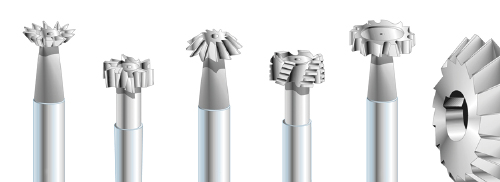

Inside the program PROPELLER are proposed circular saw blades in HSS-Dmo5 and in solid carbide, starting from diamter 12.00 mm. up to diameter 350.00 mm., with different thicknesses. The range is available with fine and coarse teeth.